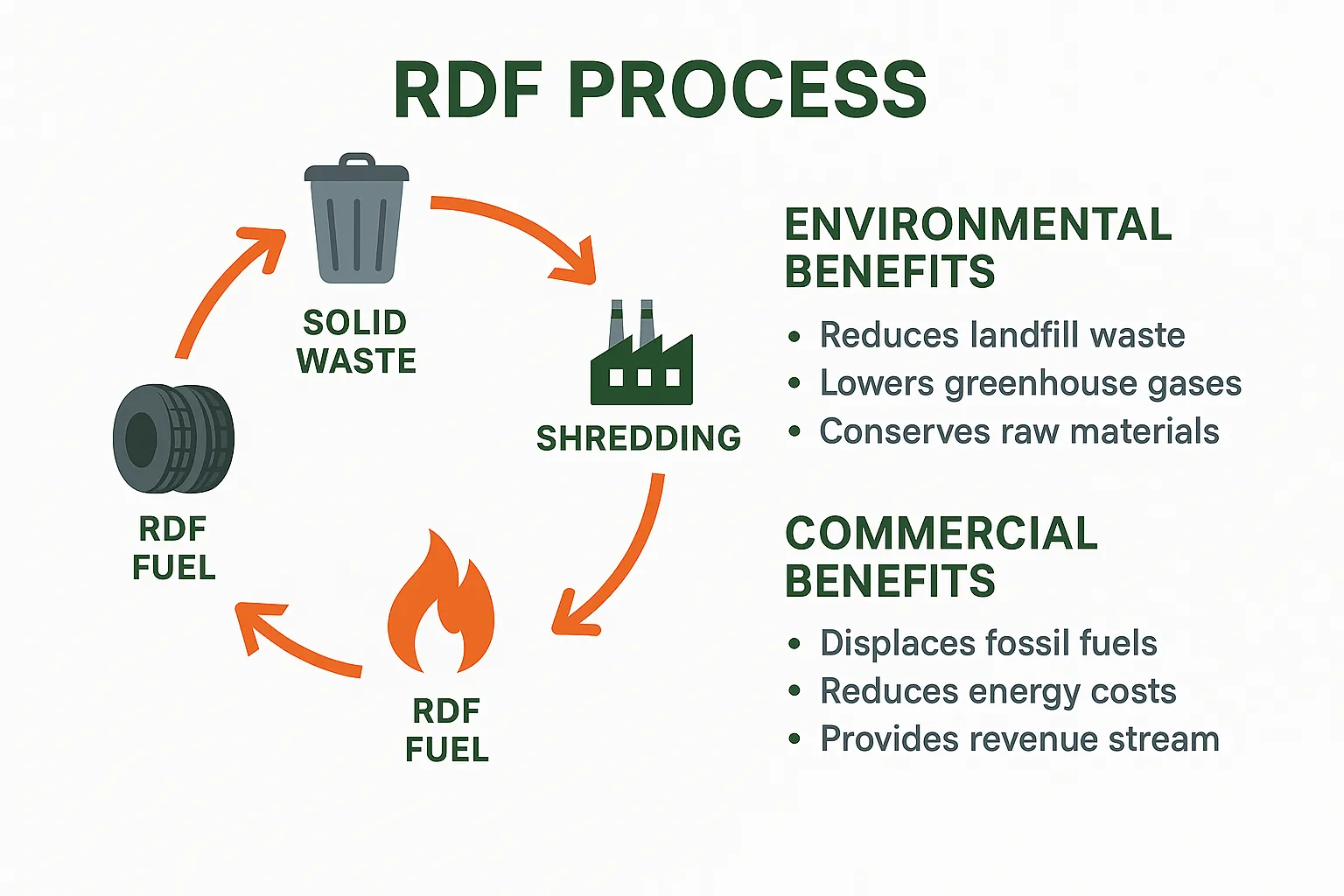

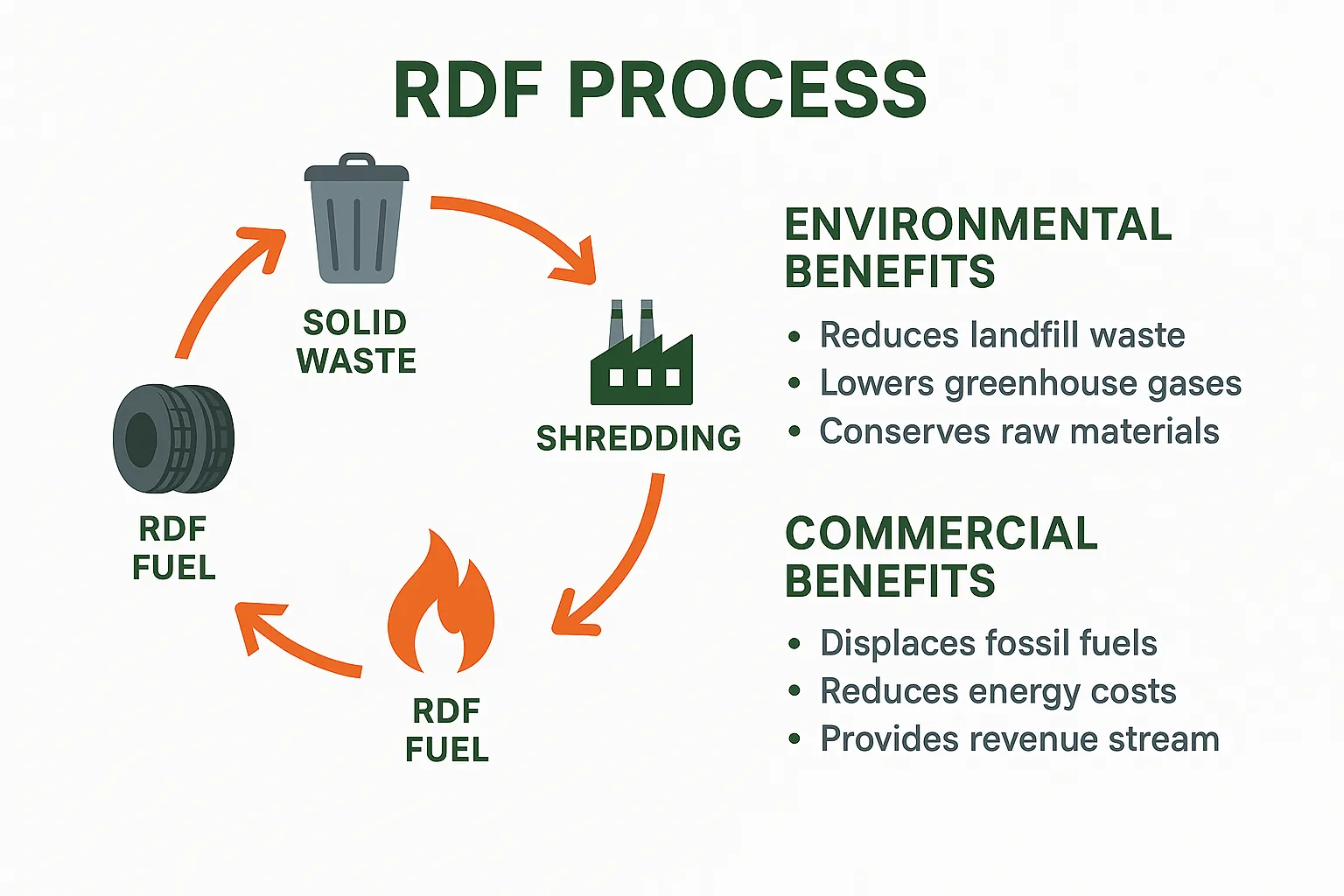

Refuse-Derived Fuel (RDF)

Refuse Derived Fuel is produced by the mechanical processing of solid waste. It involves steps like shredding, screening, and classification to produce a fuel suitable for use in incinerators or kilns.

RDF has a lower sulphur content than coal, making it more environmentally friendly and easier to meet air quality standards. It also provides a secondary use for waste, reducing landfill volumes.

Key RDF Export & Usage Facts:

- Typical processing for RDF includes shredding, screening, and air classification of solid waste.

- Compared to coal, RDF has:

- Lower calorific value

- Lower sulphur content (helps meet air pollution regulations)

- Higher chlorine content

- Low sulphur is preferred in kilns to avoid sulphur dioxide emissions and contamination of products like lime.

- RDF ash is:

- Similar to coal ash in silica (SiO₂) and alumina (Al₂O₃)

- Lower in sulphur (SO₃) and iron oxide (Fe₂O₃)

- Higher in alkaline oxides (Na₂O, K₂O)

- RDF is non-hazardous waste (different from municipal solid waste, MSW).

- European Waste List code: 19 12 10 (Fuel-like combustible waste)

- HS Code for export: 3825100000

- Usage restriction: RDF can only be imported and used by R1 recovery status incinerators.

Commercial Benefits:

- Displaces fossil fuels

- Reduces energy costs

- Creates revenue streams through recovery